A life cycle assessment of KPMB’s office interior

Article content

Open plan office layout or enclosed office spaces? New workstations or furniture reuse? A full-scale renovation or a light redesign? The choices we make when designing tenant improvements contribute just as much to the building’s carbon emissions as the structure or envelope.

To better understand the environmental impact that interior design decisions have on the total life cycle embodied carbon of buildings, KPMB Lab conducted an interior life cycle analysis of our Toronto office.

Process

Inspired by similar studies from LMN Architects and The Carbon Leadership Forum, the Lab measured the upfront carbon footprint of our office fit-out using data such as the type and quantity of materials used when designing the office.

The data included:

- Finishes (walls, ceiling, flooring, etc.)

- Fixtures (casework, doors, partitions, etc.)

- Furniture (desks, chairs, shelving, etc.)

These were collected through relevant shop drawings, identifying products and Environmental Product Declarations (EPDs), and site observation. Furniture and finishing materials reused from the previous office space were also documented, as was gross floor area (GFA).

After gathering the data and determining the EPDs (or industry average EPDs) of the items in the data set, the Lab used the One Click LCA software to calculate the total upfront carbon emissions of the office fit-out. Upfront carbon is emitted during the early stages of a material or product’s life. It includes emissions released during the extraction, processing, manufacturing, and transportation of materials.

Results

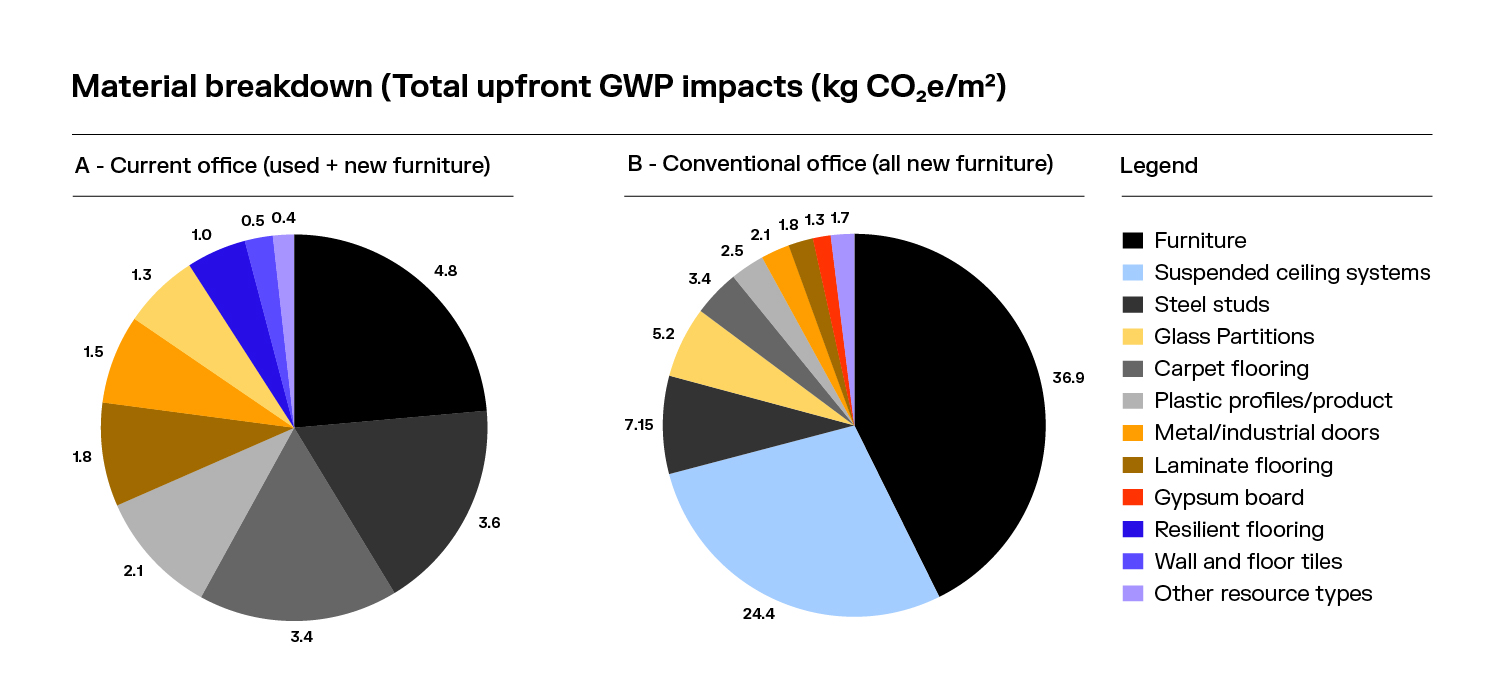

The study found that key decisions made by the design team for the interior of the office — open plan office layout, a minimal low-embodied carbon palette, furniture reuse, robust and durable furniture and fixtures — resulted in considerably lower upfront emissions.

After retrieving the results, the Lab compared the current office fit-out to other scenarios to measure the potential upfront carbon emissions if the design team made different decisions for a fit-out in the same space. For example, if we had purchased all new furniture instead of reusing furnishings from the previous office or added enclosed perimeter offices.

Through this exercise, we discovered that replacing the existing furniture with all new furniture and adding more enclosed office spaces could result in a 165% increase in the upfront carbon emissions. More materials are used when spaces are enclosed, and when additional finishes are applied to interior surfaces. All these design choices lead to higher upfront emissions.

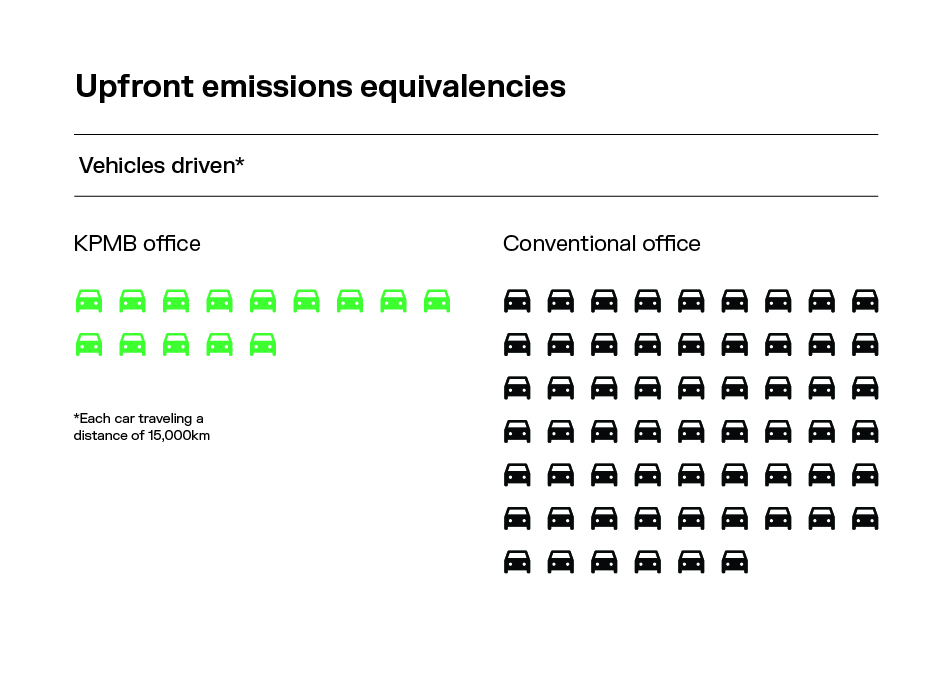

Comparing the KPMB office to a conventional office with new furniture, perimeter offices, and a suspended ceiling, the Lab found that the embodied emissions of the latter are equivalent to 60 cars travelling 15,000km –– four times more than the KPMB office which is equivalent to 14 cars travelling the same distance. Our results also show 20 kgCO2e/m2 for our office fit-out, whereas for the conventional office described above, the upfront emissions would be approximately 86 kgCO2e/m2.

The embodied emissions of a conventional office with new furniture, perimeter offices, and a suspended ceiling are equivalent to 60 vehicles travelling 15,000km — four times more than the KPMB office.

A breakdown and comparison of the emissions released by finishes, furnishings, and fixtures commonly used in commercial interiors.

Moving Forward

A key takeaway is the important role interior design decisions have on embodied carbon, especially as interior design elements are changed and upgraded over time.

The inclusion of interior design in Whole Building Life Cycle Analysis is not currently an industry standard but it is crucial to paint a more comprehensive picture of a building’s carbon footprint.

Accounting for the embodied carbon in interior design, especially at the onset of the design process, helps us make more informed decisions — whether it be using fewer and long-lasting materials or choosing low-carbon alternatives where possible. The more interior design decisions we make with the environment in mind, the more sustainably we can design.

For more information, contact the Lab team.

)

)

)